Bodriggy CEO says it all

“Born and breed” inner Melbourne suburb Abbotsford Bodriggy is a hugely popular brewpub venue…

Cost Savings with Electrolysed Water Technology in Commercial Kitchens

Uncover the financial benefits of using electrolysed water technology in commercial kitchens, detailing how eWater can cut expenses and streamline cleaning processes.

Innovative Food Safety Technologies for Commercial Kitchens in Australia and New Zealand

Discover the top food safety technologies that are transforming commercial kitchens in Australia and New Zealand. Learn how innovations like RFID, AI platforms, and electrolysed water enhance safety, reduce costs, and ensure compliance with strict food regulations.

Harnessing Electrolysed Water: A Sustainable initiative for Corporate ESG

Enhancing ESG with electrolysed water. Offering corporations a pathway to enhance their Environmental, Social, and Governance performance while simultaneously revolutionizing traditional cleaning and infection control practices.

Why Specifiers should prioritise eWater in their next Healthcare specification

In the ever-evolving landscape of healthcare design, eWater is making waves across Australian hospital projects.

Elevating Food Safety Standards: The Superiority of electrolysed water in Restaurants

What sets electrolyzed water apart is its inherent ability to deliver powerful disinfection without the drawbacks associated with traditional chemicals making it the perfect solution for restaurants.

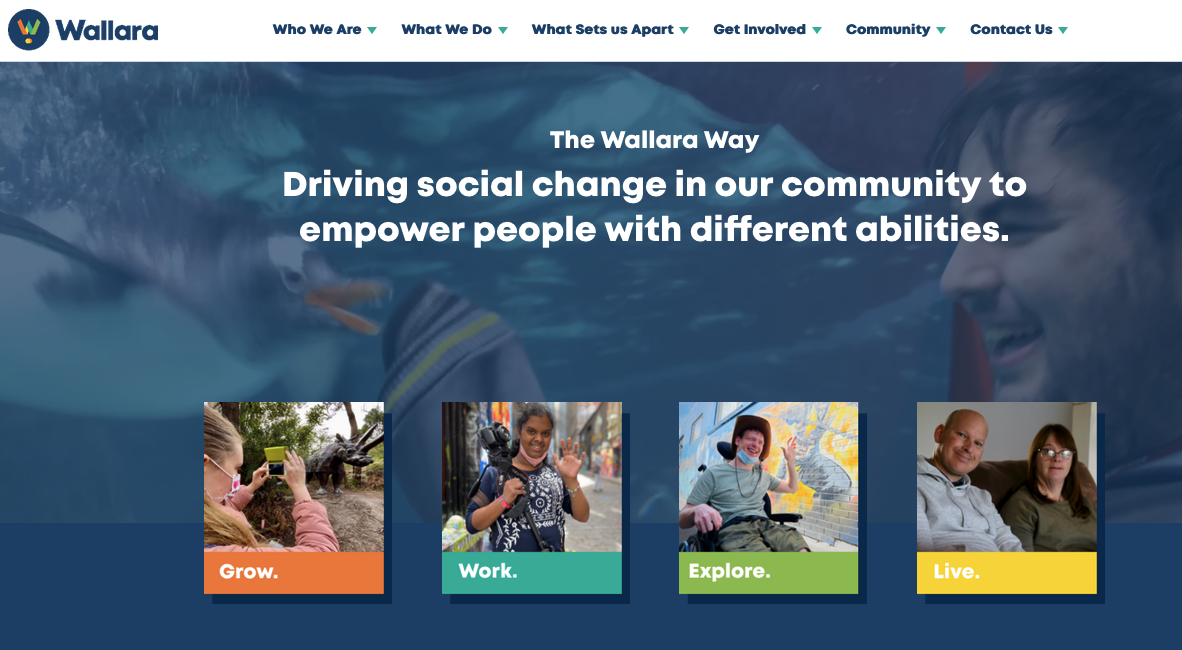

Empowering Communities: eWater's Partnership with Wallara

We're thrilled to announce our recent partnership with Wallara Australia, a not-for-profit disability services provider based in Melbourne's southeast. This collaboration is not just about expanding our production capabilities; it's about making a meaningful impact on the lives of individuals in our community.

Our Team - Marco Gritti

Marco is joining eWater as our new Commercial Director and will be responsible for overseeing customer relationships and business development across our Australian market for both specification and direct sales.